I have been working at this for months. A couple of years ago, I found out about the RepRap project. The idea behind the reprap (if you haven’t talked to me recently) is to create 3-dimensional objects on a computer, and produce them in reality by “printing” them. Today, I printed my first object.

I have been working at this for months. A couple of years ago, I found out about the RepRap project. The idea behind the reprap (if you haven’t talked to me recently) is to create 3-dimensional objects on a computer, and produce them in reality by “printing” them. Today, I printed my first object.

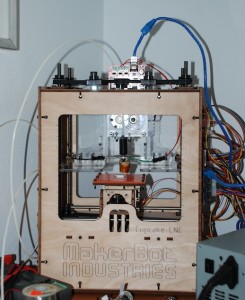

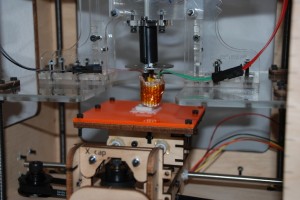

After months of struggling with various different solutions trying to make this work, I gave in and bought a Makerbot Cupcake. It’s a 3D printer. I got that a couple of weeks ago and struggled again with some design problems that I didn’t anticipate. With some help from the people in the #reprap IRC channel and a better heater from MakerGear.com, I finished up the extruder (the part that melts plastic) and this evening I printed my first piece ever.

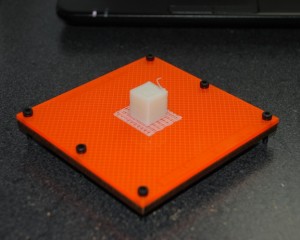

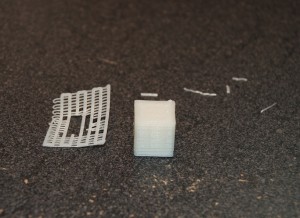

I’m super-excited and I had to share. My first piece was a very not-exciting 15mm cube. In response to a friend’s question, this is essentially the “Hello World” of the Open-source 3D printer movement.

(Note: A friend of mine noted that the “Hello World” of printers is actually a shot glass – the idea being that you toast your printer when you’re finished. This didn’t occur to me at the time, but he’s definitely right.)

Here are a few shots of the process:

So there it is. My first printed plastic object. The lattice thing there is called a ‘raft’. It’s meant to help the object cool down properly, so there aren’t warping problems. Anyway, If you have questions, thoughts, etc. Let me know!

I think the cube needs some Space Invaders to keep it company – http://www.thingiverse.com/thing:3631

So is the extruder which comes with the MakerBot not sufficient?